Workshop secrets of the Muse bench

Today Tectona opens the doors to its workshop to reveal the different steps involved in the fabrication of the Muse modular bench. In 2017, Musée National Picasso – Paris asked ÉCAL, the famous Swiss school of design, to organise a contest to renew its seating.

From oak tree to Muse bench

The design proposed by young designer Isabelle Baudraz was selected; subsequent development and fabrication were entrusted to Tectona. The oak bench combines traditional woodworking and cabinetmaking techniques used by Tectona with the precision cutting of a computer numerical control (CNC) machine.

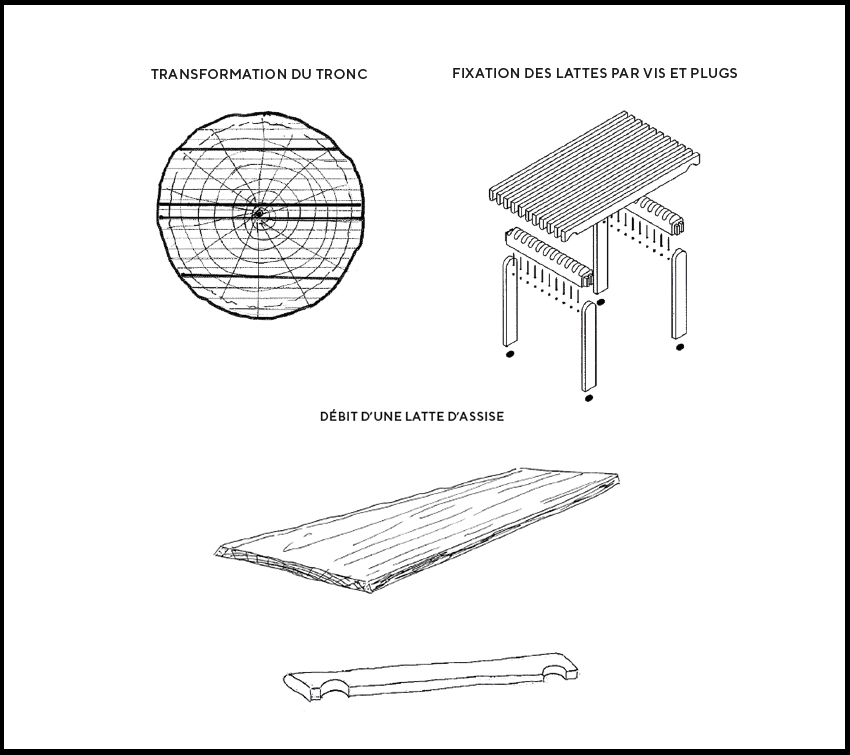

From trunk to slats

The trunk is first cross-cut (across its length) into blocks, then rip-cut (along its length) to give the following cuts, from the outermost layer to the innermost heartwood:

1. bark and sapwood, both of which are young wood still growing hence unusable in woodworking.

2. flat cuts, rift cuts and quarter cuts from which the heartwood, susceptible to cracks, is removed. These pieces are respectively cut to give the smallest to largest slats.

Finishing the slats

Once the slats are obtained, the following four operations are performed on them in turn:

1. planing to give a regular, even surface.

2. routing to transform them into a moulding with a semi-circular edge.

3. scrollsawing to create a curved cavity in the moulding.

4. cutting chamfers into the slats, to eliminate sharp edges.

And finally: Muse!

The slats are assembled together by double mortiseand-tenon joints, which confer the level of robustness required for use by the general public. Next they are fixed to two transverse supports by screws inside wooden plugs. The slats and transverse supports rest on four oak legs. Modules can be combined in twos or threes, for example, to form seating ‘islands’.